Cable-Connector Testing

Testing is required to verify the ability and specifications of cables and connectors. This is achieved by simulating real life operating conditions where cables and accessories are in constant subject to heating and cooling.

The systems share several design and safety features.

|

|

Tests and measurements are performed in accordance to the applicable IEEE/IEC standards. The system’s design is customized and depends on several factors like:

|

|

Contact us and we’ll get back to you to understand your requirements and quote you accordingly.

Cable and connector test systems are equipped with well developed, multi-feature software to add robustness.

- User friendly, attractive visual interface

- Ability to connect to existing database files and servers

- Password protected login with different user access levels

- Configurable hardware and software settings

- Automatic test mode

- Automatic data acquisition and measurement processing

- Real-time graphical and value displays

- Save, retrieve and print test reports

- Graphical analysis of test results

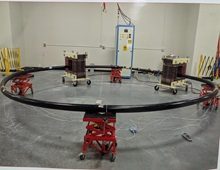

Heat Cycle Test System

This is also known as Load Cycle Test designed to raise and control the temperature for a defined period in cables, accessories or other low electric impedance loops. This simulates the loading conditions or inducing current in electric circuit up to 4000A. The system is automated, customized to requirements so as to verify cables' electric specs. It's equipped with a control console.

Connecter Test System

Automated and customized to requirements. It's equipped with a control console. The system tests the electrical specifications of connectors by simulating operating conditions through heating and cooling up to 2000A. Cable connectors are used to form connections between conductors of the same material or different ones on utilities' transmission or distribution lines.

Gallery